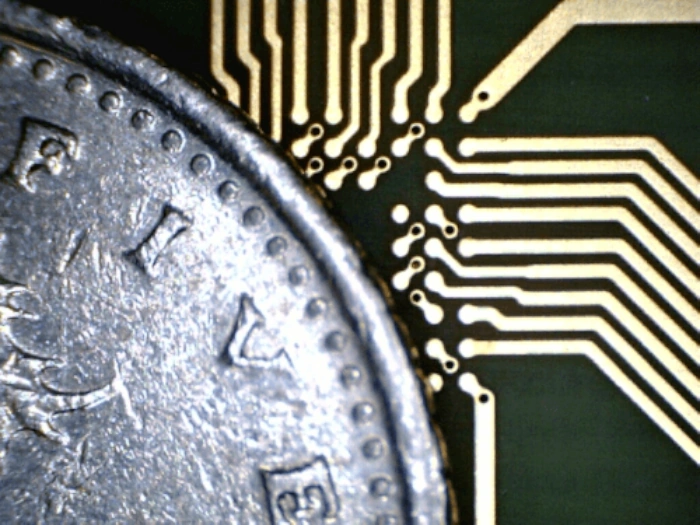

PCB Micro Vias

PCB Micro Vias, also known as uVias, are tiny holes drilled into printed circuit boards (PCBs) that play a crucial role in enabling high-density interconnect (HDI) designs.

Key Advantages of Microvias

Microvias outperform traditional through-holes in several ways, making them the go-to choice for high-performance PCB applications.:

- Microvias cram a surprising amount of connections into a tiny space. This lets us build smaller, jam-packed PCBs. That’s crucial for shrinking electronic devices, needing fewer parts, and keeping signals strong.

- Microvias shrink circuit boards, shortening signal travel time. This one-two punch minimizes crosstalk and noise, keeping your signals clean and your system running smoothly.

- Microvias being tiny cools things down better. This prevents heat from jamming up and keeps your sensitive components happy. That’s especially important for devices with lots of power or super-fast signals.

Applications of Microvias

Microvias are widely used in various electronic devices, including:

- Smartphones, tablets, and wearables wouldn’t be possible without microvias. These tiny connections pack a lot into a small space, letting designers cram all the parts you need into those sleek devices.

- Routers, switches, and other network gear use microvias to crank up data speeds and keep your connections rock-solid.

- Microvias are a game-changer for aerospace and defense. They shrink critical components and keep them working flawlessly, which is vital in those high-stakes situations.

- Microvias help build super-precise circuit boards that power medical implants, diagnostic tools, and other devices saving lives.

Microvias revolutionised PCB design and manufacturing. They enabled the creation of compact, high-performance electronic assemblies for a wide range of applications. Their ability to enhance signal integrity, reduce crosstalk and noise, and improve thermal management makes them essential for modern electronics. As technology advances, the demand for microvias will continue to grow, further driving the miniaturisation and performance of electronic devices.

Our Schmoll, Micronic, and Lenz machines are drilling superstars! They can drill holes as tiny as 0.15mm, leaving an exact 0.10mm (0.004″) diameter after plating. Because of the drill’s length and the plating process, these microvia holes typically live in materials 1.60mm thick or less.

Learn more about annular ring size when deciding on a pad size for your drilling by watching our informative video on our YouTube channel.

Contact us today with your micro via PCB design and send us your Gerber files for a quick and competitive quote.