Does Made in the UK really mean that or just...

Read MoreHalf a hole

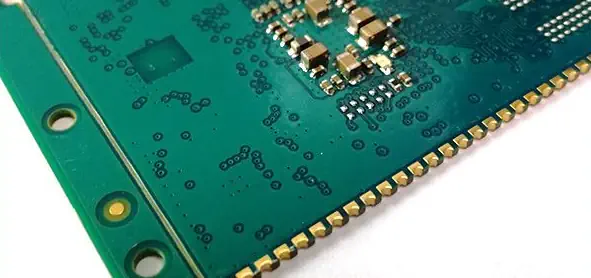

Half plated / castellated Technology. Half a hole PCB design

PW Circuits can now produce burr free half a hole PCB design, also know as castellated PCBs. Old methods of routing away half the hole resulted in a burr remaining or the plating being ripped out of the hole, but with new processing stages this can now be achieved.

Half holes, also known as castellated holes, are a type of through-hole that extends only partially through a PCB.

Unlike traditional through-holes that go completely through the board, Half a hole PCB design provide a plated surface on one side of the PCB for soldering components.

How do they work?

- Structure: Half holes are essentially plated through-holes cut in half. They have a plated wall on one side of the PCB, which acts as a landing pad for components.

- Function: Primarily used for board-on-board connections, half holes allow for the direct soldering of one PCB to another without the need for additional connectors. This provides a slimmer profile and potentially better electrical connection.

- Applications: Common applications include:

- Board-on-board connections: Combining different PCB technologies or adding modules.

- Fine-pitch SMD components: Providing a better landing pad for small components.

- RF assemblies: Used in high-frequency applications due to their reduced height.

Advantages of Half Holes

- Space-saving: Reduces overall PCB thickness.

Improved electrical connection: Direct soldering can provide better conductivity. - Cost-effective: Can eliminate the need for additional connectors.

- Enhanced reliability: Can reduce the risk of connection failures.

Contact us today for more information on your half hole PCBs.

Other PCB news blogs you might be interested in...

Is this website too complicated?

Ramblings on making our website faster and the minefield of...

Read MoreSchmoll drilling & scoring machine

New factory addition, Schmoll PCB drilling. Always improving, always updating....

Read More