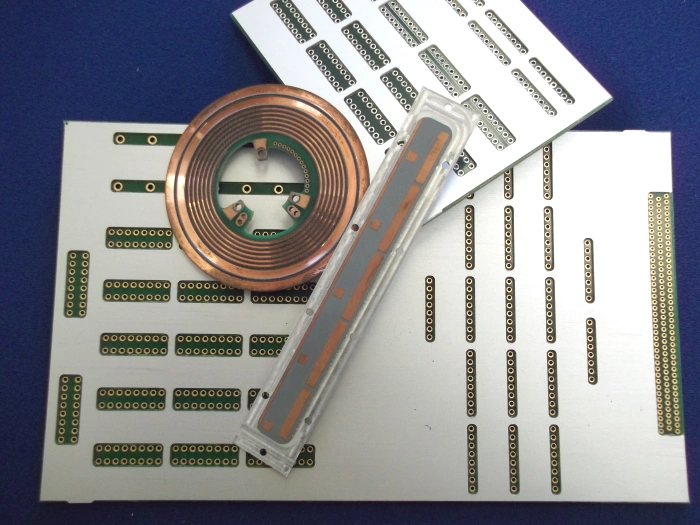

PCB heatsink bonding

PCBs with Heatsinks

The process of PCB heatsink bonding to a printed circuit board is to aid in the removal of heat. This is widely used within the electronics industry.

Aluminium is the most common metal used for heatsinks and is usally fabricated then anodized to help prevent corrosion. The heatsink can be bonded to the PCB using various different adhesives, no-flow pre-pregs, printable epoxys, thermally conductive pre-pregs and adhesive tapes.

Our experience allows us to meet tight tolerances while minimizing costs.

Contact us for more information.

Why choose an Ali-backed PCB?

Aluminum is a popular material for printed circuit boards (PCBs) due to its many advantages over other materials, such as fiberglass and ceramic. Here are some of the key reasons why aluminum is often used for PCBs.

Superior Thermal Conductivity: Aluminum is an excellent conductor of heat, which is crucial for dissipating heat away from sensitive electronic components. This property makes aluminum PCBs well-suited for applications where heat generation is a concern, such as power electronics, high-power LEDs and motor control circuits.

Durability and Strength: Aluminum is a robust material that can withstand mechanical stress and vibration. This makes aluminum PCBs less susceptible to damage during handling, transportation and operation.

Lightweight and Compact Design: Aluminum is relatively lightweight compared to other PCB substrates, allowing for more compact and space-efficient designs. This is particularly beneficial for applications where weight and size are critical considerations, such as aerospace and automotive electronics.

Electromagnetic Shielding: Aluminum PCBs can provide effective electromagnetic shielding so preventing interference from external electromagnetic fields. This property is important for applications where sensitive electronics are susceptible to electromagnetic noise.

Dimensional Stability: Aluminum PCBs exhibit excellent dimensional stability, meaning they maintain their shape and size even under extreme temperature fluctuations. This stability is crucial for ensuring the long-term reliability and performance of electronic circuits.

Environmentally Friendly: Aluminum is a recyclable material, making aluminum PCBs a more environmentally friendly choice compared to other PCB substrates.

Don’t forget to check out our YouTube channel with an ever expanding library of PCB videos. We can help you make informed choices when designing you circuit boards. This could help you speed your PCB at the manufacturing stage.